Engineering Design Service

Business Development & Market Intelligence

At DRVBOT, our Business Development Management (BDM) goes far beyond sales. We act as your strategic engineering partner, starting with deep market research and technical benchmarking to identify the most reliable, cost-effective, and performance-driven solutions. Leveraging our strong ecosystem in the Turkish industrial market, we connect you directly with proven suppliers, manufacturers, and producers across robotics, automation, and heavy engineering. This approach reduces risk, shortens lead time, and ensures your project is built with the right technology, the right partners, and the right commercial strategy—aligned with both engineering excellence and business objectives.

Concept & Detailed Design Engineering

We transform ideas into structured, investment-ready engineering solutions through a disciplined Concept Design (CD) and Detailed Design (DD) process. Using SolidWorks, we develop precise 3D models, system layouts, and multiple design alternatives to identify the optimal technical solution. Early feasibility studies validate space, performance, and operational constraints before major decisions are locked. Through clear visualization, technical storytelling, and professional presentations, we help stakeholders, customers, and investors understand and approve solutions faster. High-quality renderings and realistic animations bring machines and workflows to life, while Detailed Design translates concepts into manufacturing-ready systems with defined interfaces, tolerances, and integration-optimized engineering.

Mechanical Design & Engineering Validation

Our Mechanical Design (MD) services deliver production-level engineering built for real-world performance. We prepare complete shop drawings, assembly drawings, and manufacturing documentation aligned with international engineering standards. Every design is validated through mechanical analysis using ANSYS, including structural integrity, load capacity, stress distribution, deformation, and safety factor verification. This simulation-driven approach minimizes risk, optimizes material usage, and prevents costly redesigns before fabrication. To ensure full production readiness, we develop detailed Bills of Materials (BOMs) with precise specifications and quantities, supporting supplier selection, cost control, and seamless coordination between engineering, procurement, and manufacturing teams.

Automation, Control & Programming

DRVBOT delivers intelligent automation and programming solutions designed for reliability, safety, and scalability. We develop tailored electrical and automation schematics that ensure smooth installation, commissioning, and long-term maintainability. Safety is engineered into every system through structured risk assessments, safety concept design, and compliance with industrial standards, including emergency logic, interlocks, and fail-safe operation. Our PLC programming covers logic development, testing, and deployment, with precise I/O mapping and field wiring coordination. We seamlessly integrate sensors, drives, robots, and control systems to deliver efficient, future-proof automation that supports operational excellence and system expansion.

Production Tailored Made

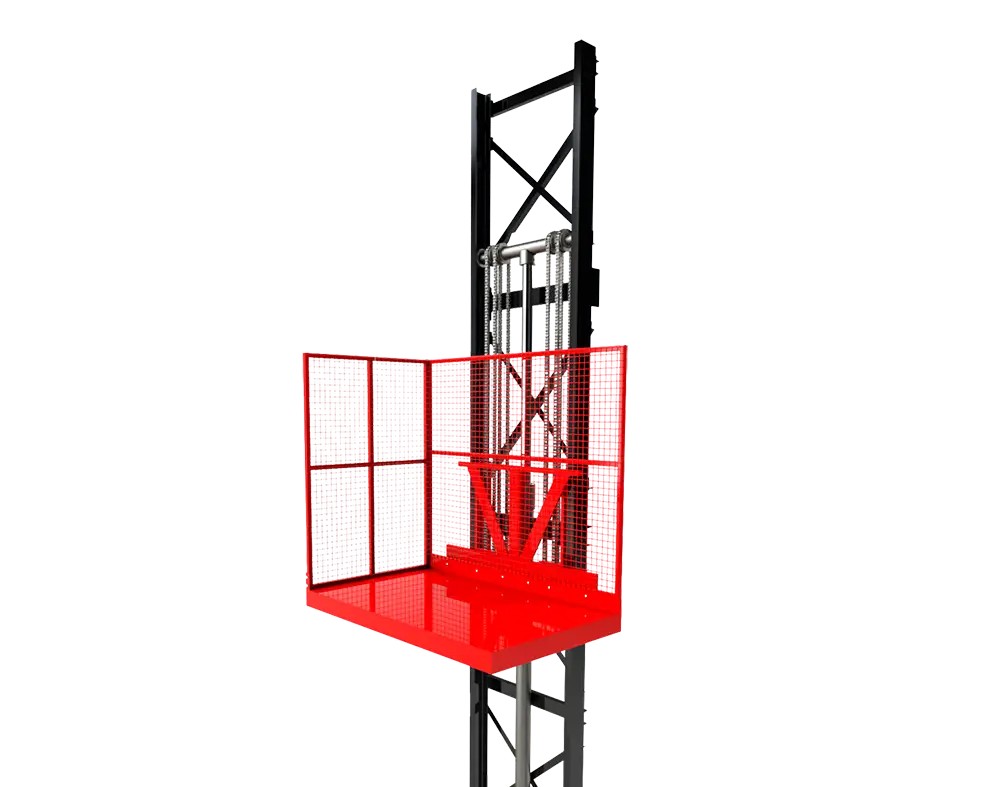

Hydraulic Vertical Load Platforms

These hydraulically operated platforms are used in factories, buildings, small and medium-sized businesses, and essentially all spaces with differences in floor and elevation. Also used as platforms for disabled access, these platforms offer significant advantages in terms of both price and construction time as they do not require a shaft or machine room.

Custom Transfer Cart

DRVBOT Trackless Transfer Carts offer safe, precise, and flexible transportation of loads from 1 to 400 tons within industrial facilities, featuring remote control or autonomous operation, ergonomic design, and advanced collision-prevention systems. With customizable top tables, multiple wheel and steering options for high manoeuvrability, and optional features such as hydraulic lifting and self-adjusting welding rotators, they provide a reliable and adaptable solution for heavy-duty industrial applications.

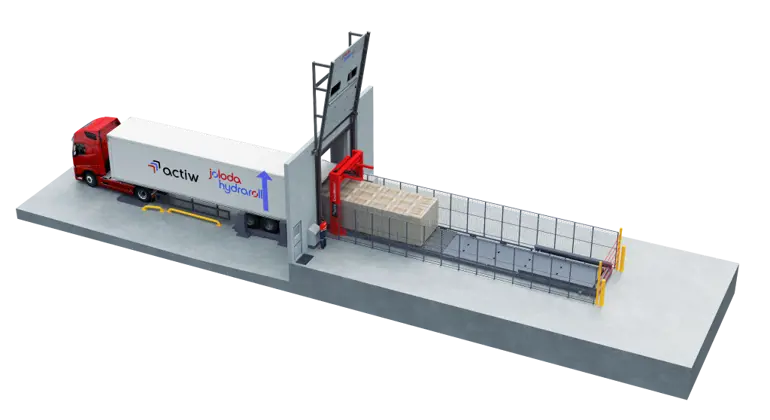

Container Loading & Unloading

DRVBOT’s Container Horizontal Loading & Unloading Solutions automate container handling to deliver faster, safer, and more efficient operations. Our systems load containers in as little as 5 minutes and unload in under 10 minutes, using single-operator operation, automatic height adjustment, and a sliding plate mechanism that maximises space utilisation while protecting cargo. By eliminating manual handling, businesses reduce labour costs, improve safety, minimise damage, and achieve faster turnaround times.

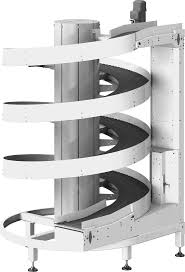

Conveyor System

At DRVBOT, we design and manufacture tailor-made conveyor solutions to match each application. Our portfolio includes flexible conveyors, spiral conveyors, and custom conveyor systems for boxes, totes, and pallets, with fully customized dimensions and payload capacities. From compact layouts to heavy-duty handling, we deliver reliable, application-specific conveyor solutions built for performance and scalability.

Installation After-Sales

Installation & Integration

On-site installation and system integration

Mechanical, electrical, and automation commissioning

Performance testing and final acceptance

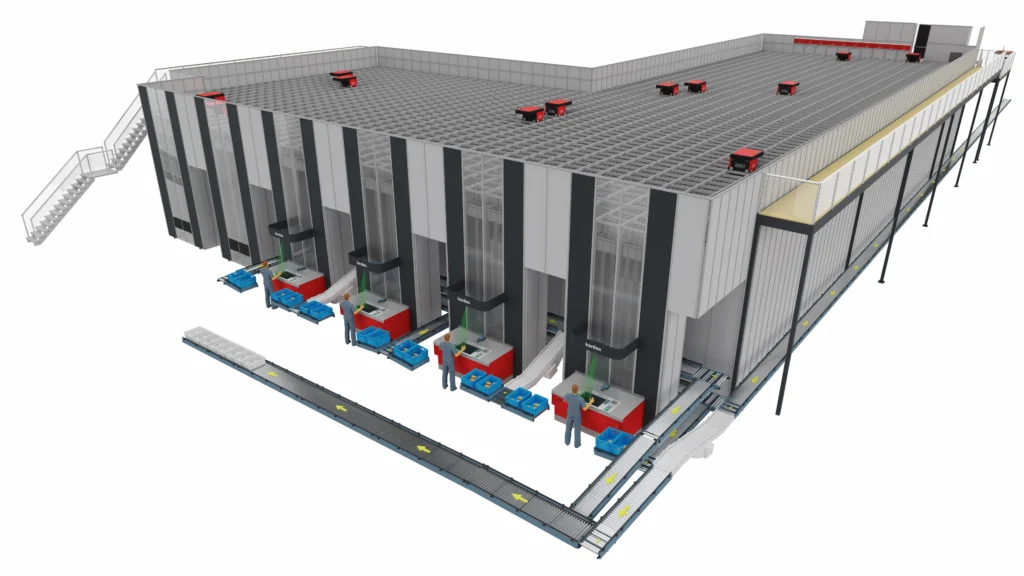

Autostore – 4Ways Radio Shuttle – ASRS – Conveyor

After-Sales Support & Maintenance

Reliable support throughout the system lifecycle:

Preventive maintenance (monthly/quarterly)

Emergency breakdown support (24/7 or as agreed)

Spare parts inspection and replacement

Software diagnostics (PLC, SCADA, where applicable)

Monthly service reports with performance KPIs